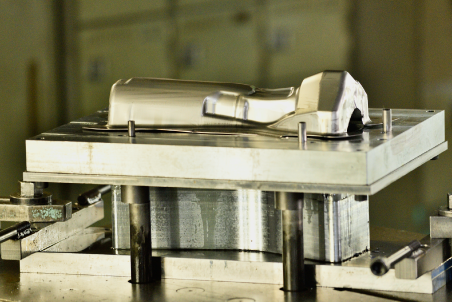

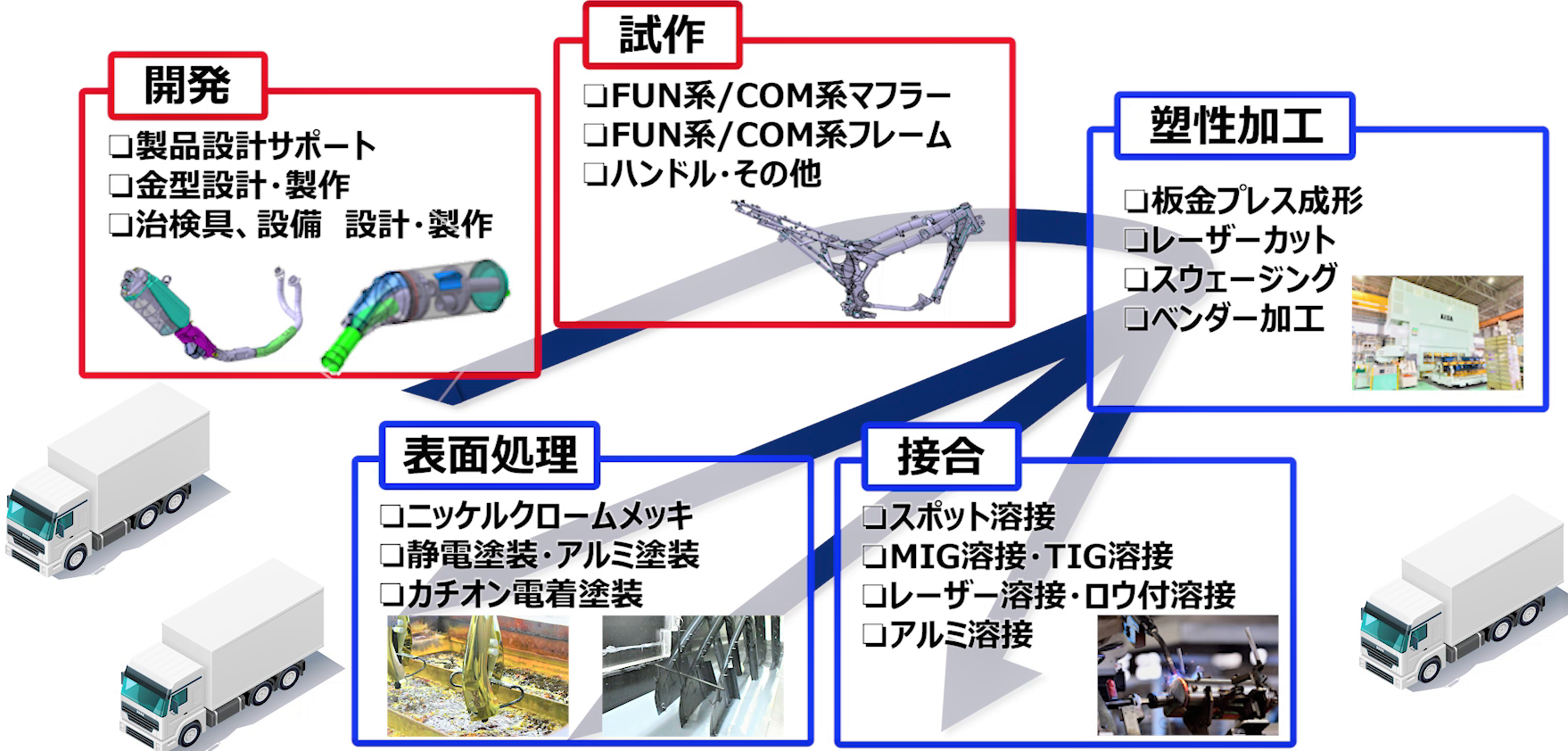

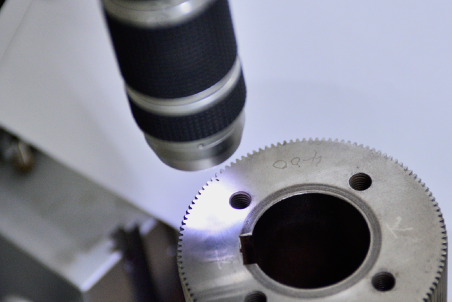

Pressing

Our products come from a variety of presses, including a 1200-ton hydraulic press, 800-ton transfer press, and a 600-ton transfer press. We make a variety of reliable products, both thick and thin, for use in 4- and 2-wheel vehicles and for general use.

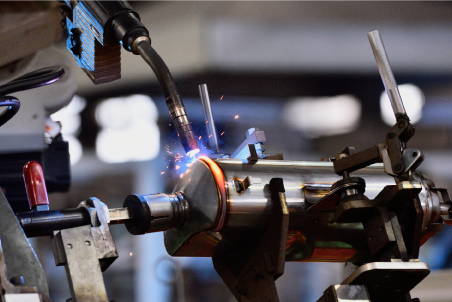

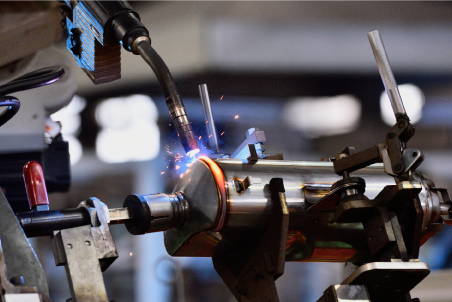

Welding

Thanks to our meaningful ideas and know-how regarding welding robots, computers, MIG/TIG, spot welding, etc., this line can produce products that are high efficiency and high quality, in a variety of models and in small numbers.

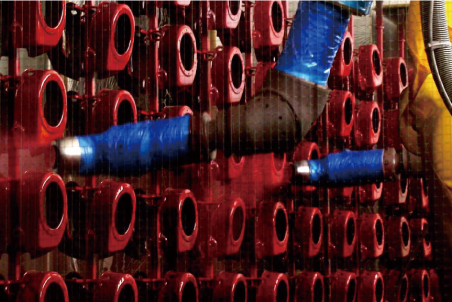

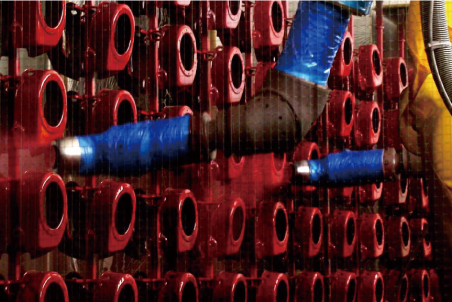

Electrostatic coating

The overhead conveyor connecting the preprocessing line with the coating process uses a power and free-style direction branching system. In the coating process, by using a floor-wide pin conveyor and welding robots with metallic-base paint electrostatic bell spray coaters, the line offers both high efficiency and high quality. By being able to coat iron, aluminum, and other materials with heat-proof, acrylic, and melamine general coatings, we can meet a wide range of customer needs. We also use eco-friendly coatings (as per EU regulations) as a means of taking care of the environment.

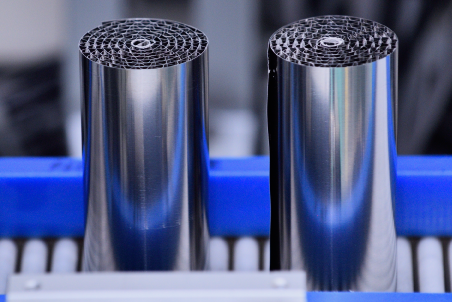

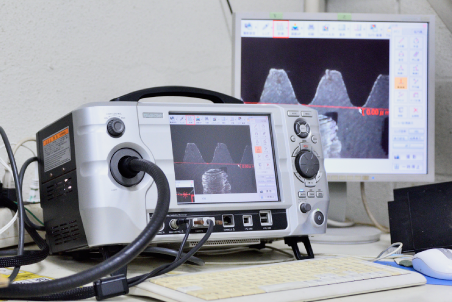

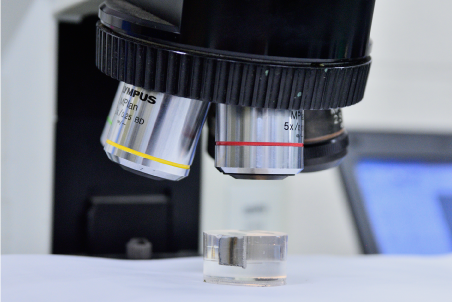

Nickel/chrome plating

Our automatic line is set up for efficiency, meaning a processing output of 300,000m2 per month (2 in parallel), which allows us to answer needs for a variety of parts under highly reliable management with a focus on quality assurance as the final step in the entire process.

Cation coating

This state-of-the-art electrodeposition coating system in a revolutionary line structure allows for lower costs and fewer resources. Using cation electrodeposition coating for 4-wheel vehicle suspension parts results in the best in corrosion protection. We also use eco-friendly coating (EU regulations) as a means of taking care of the environment.