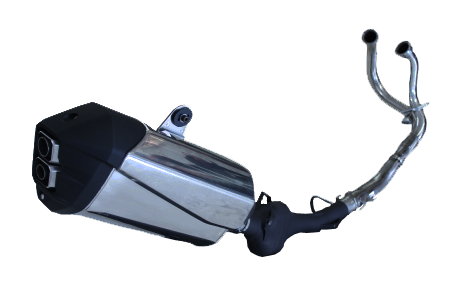

World-Renowned New Africa Twin Muffler

The Muffler, Reborn

Yuki Hanahara,

New Model Block,

New Model Planning Group

Large mufflers need looks, sound, and output performance

None of what applies to regular commuter models is important here – this was for a high spec product. We used a state-of-the-art welder to get minimum sputtering and warping.

For sound and output performance, we need tolerances on the scale of a tenth of a millimeter. To accomplish this, we needed to make sure our company and our cooperating manufacturers understood the difference between large and commuter mufflers and the need to manufacture components one at a time.

Out of all the large mufflers, the CRF1000 was said to be the most difficult to make, and while it was hard work, I think we were able to make the best muffler we’ve ever made.